Scissor Lift Safety Toolbox Talk - Safety Checklist & Resources

Sept. 18, 2021

Learn how to operate and maneuver scissor lifts safely around your job site.

Scissor lifts provide a platform for workers to perform job tasks at elevated levels. Scissor lifts are used in a variety of industries, including construction, retail, entertainment and manufacturing. Scissor lifts are different from aerial work platforms because the lifting mechanism moves the work platform vertically using crossed beams (the "scissors").

Due to the nature of a scissor lift design, many scissor lifts are covered under OSHA’s Scaffolding standard.

The primary risks associated with scissor lifts include falls from the platform and tip-overs. Scissor lifts can experience a collapse of the cross beams; however, this occurrence is rare as long as the operator follows manufacturer directions and the machine is serviced at recommended intervals.

The largest scissor lift brands today are JLG and Terex's Genie.

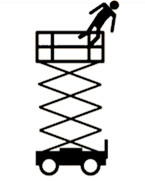

Scissor Lift Design

A scissor lift is essentially a mechanical scaffold that is capable of moving. Typically scissor lifts enable working heights 25-50'. Scissor lift platforms are typically 24-36" deep and 48-72" wide, and they are capable of lifting 1 to 4 people depending on weight and lift capacity. Each model is different, with its own specifications indicating max height and weight. You should always check specifications before loading and operating a scissor lift.

The lift can be controlled at the base or on the platform. The ability to move while extended is a convenient feature, but it also presents risks - many manufacturers recommend not maneuvering the lift while the platform is extended.

Source: OSHA

Notes: Scissor lift gets its name from the cross beams "scissors" that raise and lower the platform.

General Safety Measures

It is important to assess the worksite and identify all possible hazards in order to select the appropriate equipment for the task. Scissor lift operators need to evaluate and implement effective controls that address fall protection, stabilization and positioning. Only trained workers should be allowed to use scissor lifts.

Fall Protection

Scissor lifts must have guardrails installed to prevent workers from falling. Most manufacturers include top and mid rails installed along the perimeter of the platform. These rails can be used to attach lanyards and harnesses. Certain models with platforms that extend may have rope for rail sections - extra care must be used around these sections.

- Check to see that a guardrail system is in place before working on the scissor lift.

- Only stand on the work platform; never stand on the guardrails.

- Keep work within easy reach to avoid leaning away from the scissor lift.

Notes: Workers can fall from the scissor lift platform. It is important to never stand on the railing. Workers can take extra caution by attaching a body harness to the railing.

Stabilization

Operators should ensure that the scissor lift is stable and will not tip over or collapse. The operator should observe the floor and verify that it is level and firm. Most scissor lifts require a flat surface, while some rough terrain scissor lifts are capable of handling uneven surfaces.

- Most manufacturers instruct operators not to move the lift while it is in an elevated position.

- Use the scissor lift outside only when weather conditions are good. If you do use a scissor lift outdoors, make sure it is not overly windy. Most outdoor scissor lifts are limited to 28 mph winds.

- The load rating should never be exceeded. Heavy loads increase the risk of equipment collapse.

Scissor lifts can tip over if they are used on an uneven surface, if they are struck by a moving object such as a truck, or if they maneuver while extended and hit an obstacle such as a tree.

Notes: Scissor lifts can tip over if they are struck at the base by a moving object or if they hit an object while moving extended.

Positioning

Operators should position the scissor lift to avoid crushing and electrocution hazards. Crushing can occur if the scissor lift moves and crushes a bystander against another object. Electrocution can occur if the scissor lift extends into electrical lines.

The scissor lift operator should be cognizant of arc flash risks too. Electricity can arc or jump from the power line to the scissor lift or worker. Electrocution can occur even if neither the scissor lift nor the worker touches the power line.

Notes: Scissor lift operators need to be very careful whenever raising and lowering the platform, as well and maneuvering the lift along the ground.

Group Discussion Topics

- Is the scissor lift in good condition (for example, tires, hydraulic lines, signage, etc.)? Perform a visual inspection daily.

- Are there any potential risks at elevated levels nearby (for instance, power lines, gas pipes, etc)?

- How safe is the workplace floor surface to operate a scissor lift?

- How many persons will be on the platform? Does the combined weight of the persons and their gear exceed weight limits?

- What could cause the scissor lift to tip over?

Find Similar Articles By Topic

#material handling #construction #toolbox talks #scissor lifts