Skid-Steer Loaders: A Complete Guide

Oct. 3, 2021

Skid steers are among the most popular compact construction machines found at job sites because they are cost-effective and can be used for a wide range of applications.

What Is A Skid-Steer Loader?

A skid-steer loader is a small, rigid-frame, engine-powered machine with lift arms that can attach to a wide variety of attachments and tools. Skid-steers are among the most common pieces of machinery found at job sites today due to their versatility, ease of operation, ability to tackle a wide range of jobs, and low cost compared to larger machinery.

Most skid-steer loaders are able to use a wide range of specialized buckets and attachments powered by the loader's hydraulic system. The ability to easily swap attachments and buckets makes skid-steers one of the most popular compact construction machines found at job sites today.

History

The first skid-steer loader was a three-wheeled machine invented by brothers Cyril and Louis Keller in Rothsay, Minnesota, in 1957. The machine got its name because it was able to turn around within its own length and it operated similar to a conventional front-end loader.

Melroe Manufacturing in Gwinner, North Dakota, purchased the rights to the Keller's loader in 1958 and hired the Keller brothers to continue developing the machine. The first machine developed under Melroe ownership was the M-200 Melroe, a self-propelled loader introduced in 1958 that featured two independent front-drive wheels and a rear caster wheel. The M-200 had a 12.9 horsepower engine and a lift capacity (ROC) of 750 pounds.

Melroe continued developing the skid-steer line, and later in 1962, it adopted the well-known Bobcat trademark. Today, Bobcat continues to be an industry leader in the skid-steer category. Other notable skid-steer manufacturers include Caterpillar, Case, ASV, Komatsu, Wacker Neuson, and John Deere.

Choosing The Right Skid-Steer Loader

The wide range of skid-steer models available on the market today means that you will have to narrow down your selection based on your job needs. Picking a skid-steer with too little or too much capability can result in inefficiencies or downtime, so it's important to figure out what you'll need beforehand.

Horsepower & ROC

Skid-steer loaders typically are categorized by their horsepower, rated operating capacity (ROC, which is how much weight the machine can lift), and operating weight (how much the machine weighs). A typical skid-steer loader weighs between 2,500 and 6,000 pounds and has a rated operating capacity of 700 to 2,500 pounds.

Generally, skid-steer loader models are categorized into three categories:

- Small frame: Under 1,750 pounds ROC and under 50 horsepower. Small frame skid-steer loaders tend to be ideal for smaller jobs such as landscaping, building site development and underground construction.

- Medium frame: 1,751-2,200 pounds ROC and 50-70 horsepower. Medium frame skid-steer loaders are the most popular category in the construction industry.

- Large frame: Over 2,200 pounds ROC and over 70 horsepower. Large frame skid-steer loaders are used for grading and excavating, roadbuilding and heavy lifting applications. Attachments that require a high-flow machine (such as a wheel saw or planer) work best with high horsepower large frame models.

The most popular size in the construction industry is the 1,751-to 2,200-lb. ROC machines. As the ROC increases between machines, so too does the horsepower of the engine. - Greg Rostberg, Bobcat Co.

In addition to weight, ROC and horsepower, you should check the physical dimensions of the machine if your job site has size restrictions. Some larger machines might not be able to navigate through narrow passages. Most skid-steers are compact enough to transport on standard trailers.

When you select a machine based on its ROC and weight, always factor in some padding for unknowns. For instance, if your job requires a ROC of 2,100 pounds, you might be better-suited upgrading to a large frame rated at 2,200 pounds or more to ensure your needs are covered.

Terrain

Skid-steer on the market today include both wheeled and tracked (also called "compact track loaders") models.

Wheeled skid-steers tend to perform better on smooth and stable surfaces such as concrete, asphalt, and wood. Generally speaking, wheeled skid-steers are better suited for most indoor applications. Also, wheels tend to cost less than tracks.

Tracked skid-steers outperform wheeled skid-steers on uneven and less sturdy surfaces such as snow, sand and dirt. Tracks tend to be more versatile than wheels, but they are slower to move and they wear down faster on smooth surfaces. Also, tracks require a higher level of normal maintenance to keep the tracks, bogey wheels, sprockets, and other components in working order.

Radial Lift Versus Vertical Lift Loader Arms

Most skid-steer models on the market today feature either a radial lift or vertical lift loader arm. Both look and function very similar, but there are small differences that can make a difference on the job site.

- Radial Lift features a simpler design and loader linkage. The loader lift path is similar to a rounded arc. Radial lift provides greater forward reach for over 80% of the lift path, with the greatest forward reach at mid-range heights.

- Vertical Lift offers more reach at max height, and it has a much more complex loader linkage. The loader lift path is more like a straight light up and down, rather than the rounded arc of a radial lift. Vertical lift provides more reach at full height without a loss in performance.

Attachment Compatibility

Skid-steer attachments enable you to use the machine for a wide range of applications. The conventional skid-steer bucket can be removed in order to use other specialized buckets or attachments. Attachments often utilize the loader's hydraulic system, so it is important to look at the machine specs and make sure it can meet the attachment specs.

Attachment applications vary greatly. Sample skid-steer attachments can include backhoes, hydraulic breakers, pallet forks, angle brooms, sweepers, augers, mowers, snow blowers, stump grinders, tree spades, trenchers, dumping hoppers, pavement millers, rippers, tillers, grapples, tilts, rollers, snow blades, wheel saws, cement mixers, and wood chippers.

Other Bells & Whistles

Manufacturers continue to develop and integrate new skid-steer technology and features. Extra optional features can include telematics, rear cameras, auto ride control, cushioned cylinders, LED sidelights, heated cloth air seats, and auto-reversing fans.

How To Operate & Drive A Skid-Steer

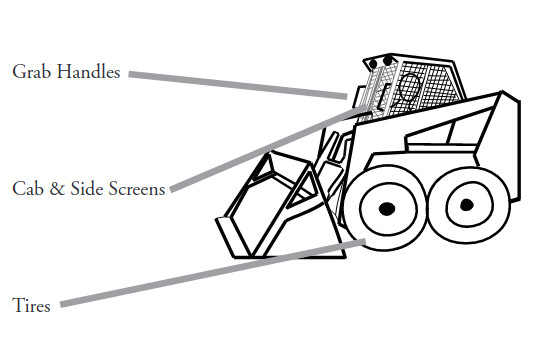

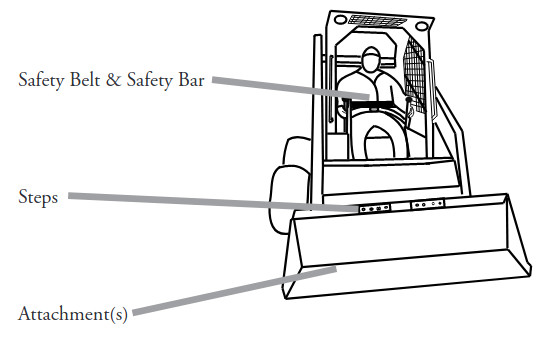

Skid-Steer Components

1. Pre-inspection

Always read the manual before operating the skid-steer for the first time. Also, be sure to perform a visual inspection at the beginning of each day to verify that machine components are in good working condition (fluid levels are correct, no fluid leaks, wheels and tires are in good condition, steering functions normally, hydraulics are in working order).

Scan the job site area and look for bystanders. Make sure other people are aware of the machine.

2. Enter the machine

Skid-steers can be difficult to get in and out of the cab because of the compact design. Some skid-steer models feature side entry, while others require the operator to enter through the front. Always use three points of contact when you enter and exit the cab in case a limb becomes stuck. Once you enter the cab, fasten your seat belt.

3. Start the engine

Start the skid-steer engine and listen for abnormal engine sounds. Also, be on the lookout for odd-colored exhaust as that could indicate internal engine issues.

Control configurations vary based on model and manufacturer. Be sure to read the manual and understand where all machine controls are located.

4. Learn how to control the boom and bucket

Test raising and lowering the boom, as well as opening and closing the bucket. Typically you can control the movement by moving the joystick right and left, forward and back.

5. Drive the skid-steer

Practice driving the skid-steer by moving the drive joystick forward and back. Be sure that the boom is raised off the ground but not too high where it obstructs your view. It's important to note that lifting the bucket high changes the center of gravity and increases the risk of the machine tipping over.

Additional Safety Considerations

Although skid-steers are classified as compact construction equipment and are smaller than other machines at jobs sites (such as a large excavator or dozer), skid-steers still can be dangerous to operate and require proper training to prevent workplace injuries.

Skid-steers are prone to rolling over, which can result in serious injuries to the operator and bystanders. A skid-steer loader can roll over when it becomes unstable or imbalanced. Overloading, carrying loads too high, operating on rough or uneven surfaces, adding attachments or driving too fast for conditions can cause the loader to become unstable.

When carrying loads, you should distribute the load evenly on the attachment. Also, secure unstable loads so they do not move. When driving with loads, keep the load low to the ground and move slowly to maintain control. Use extra caution when operating on hilly or uneven surfaces. Also, slow down when making turns.

Take care to prevent crushing accidents. Common crush points on skid-steers include:

- Between the lift arm and cab

- Between the lift arm and frame

- Between the attachment and frame

- Under the attachment

Resources

OSHA Skid-Steer safety

How to Operate a Bobcat // Skid-Steer Training