Forklift Safety Toolbox Talk - Safety Checklist & Resources

Sept. 18, 2021

Forklifts are common equipment found at job sites and industrial warehouses. Learn how to operate and use forklifts safely.

Forklifts, also known as powered industrial trucks (PITs), are a common piece of equipment found at most job sites and industrial warehouses. Forklift types and applications can vary (learn more about different forklift types), and each type presents different safety requirements.

Generally speaking, forklifts are less dangerous than a large rough terrain crane or excavator; however, they still present risks that can cause workplace injuries.

According to OSHA, forklift overturns are the leading cause of fatalities involving forklifts, and they represent about 25% of all forklift-related deaths. Each year in the United States nearly 100 workers are killed, and another 20,000 are seriously injured in forklift-related accidents (see NOISH report).

Diesel forklifts are designed to be used outdoors because they release fumes harmful to humans. Using a diesel forklift indoors without adequate ventilation is dangerous.

Many factories use colored tape to indicate forklift zones, so workers are aware of their surroundings. Also, mirrors near corners help forklift operators and workers see each other if their line of sight is obstructed by shelving.

Handling The Forklift Load Preparation

Always ensure that a forklift load is centered and balanced. Off-center loads can cause the forklift to tip over.

- Secure the load, so it is stable and ordered.

- Inspect the load and make sure it has not been damaged - if merchandise has been damaged it must be secured with wrapping or banding.

- Center the load.

- Use caution when handling off-center loads that cannot be centered. Move slower and use more caution.

- Distribute the heaviest part of the load nearest the front wheels of the forklift. This helps center gravity.

- Do not overload. Understand the forklift's capacity and do not exceed it. Be sure to factor in the weight of any attachments used.

- A forklift's capacity is rated for a specified load center. If the load is off-center, improperly distributed, or oversized, it may exceed capacity and unbalance the forklift.

- Use the load extension backrest.

Takeaway: The top image shows a properly balanced forklift load. The bottom image shows an imbalanced and dangerous load. Improperly balanced loads can cause the forklift to tip over.

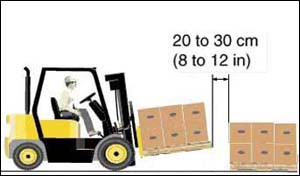

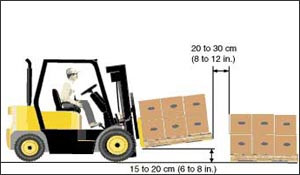

Approaching the Forklift Load

- Approach the load slowly, and stop 8-12 inches in front of the load.

- Position the truck perpendicular to the front of the load with the forks at the correct height.

- Set the direction control to neutral.

- Do not maneuver the forks until the forklift has come to a full stop and brakes are set.

- Use the inching pedal to creep the load to the stack.

Notes: Always stop 8-12 inches in front of the load to allow adequate room to maneuver the forks.

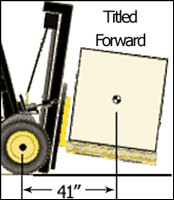

Mast Position

- Monitor the load while moving the mast. Loads can become unbalanced.

- Use caution when tilting loads. Do not tilt forward with forks elevated except when picking up or depositing a load.

- When stacking or tiering, tilt backward only enough to stabilize the load.

- Travel with the mast tilted back to keep the load stable.

- Tilt the mast forward carefully when positioning the load onto the stack.

- Never travel with the load tilted forward. Tilting the load forward increases the load distance and makes the load less stable.

Notes: The mast should be vertical when approaching a load.

Notes: Use caution when the mast is tilted forward. Tilting the mast forward increases the load distance and increases the risks of imbalance.

Notes: Tilting the mast back reduces the load distance and helps center gravity.

Positioning Forklift Forks

- Ensure the forks are level before inserting them into the pallet.

- The forks must be placed under the load as far as possible. This helps center gravity.

- Slide the forks into the pallet until they are fully under the load. The forks should be at least two-thirds the length of the load. If you are unable to get two-thirds of the load length, you should try to find a different forklift to do the job.

- Be careful that the forks do not puncture or hit items on the other side of the pallet.

- Center the weight of the load between the forks. Adjust the forks to distribute the weight evenly.

- Tilt the mast back carefully to stabilize the load. Tilting the mast helps stabilize the center of gravity.

Notes: Slide the forks into the pallet until they are fully under the load. Be careful not to extend beyond the pallet and hit other objects. The forks must be at least two-thirds of the way under the pallet to lift it safely.

Lifting the Load

- Check that there is enough overhead clearance before raising the load. Check for overhead installations, lights, pipes, etc.

- Carefully lift the load up above the lower stack about 4 inches and make sure it is stable.

- Lift the load and then tilt the mast back slightly to rest the load against the backrest extension.

- Ensure that the load is not caught on any obstructions, tied down, or otherwise moving something it should not be.

- Slowly return the lift control lever to the neutral position.

Notes: Lift the load slowly and carefully 4 inches up. Check that the load is balanced in control.

Lowering the Load

- Be aware of falling loads and striking objects when lowering the load.

- Return the mast to the vertical position before lowering the load.

- Lower the load so that its lowest point is 6 to 8 inches from the floor.

Notes: Tilting the mast backward helps stabilize the load.

Group Discussion Topics

- Is your forklift in good condition? (i.e. tires, hydraulic lines, signage, etc.). Do a visual inspection daily.

- What are some of the forklift hazards specific to your workplace?

- Is the forklift designed to operate inside a warehouse or outdoors?

- Do bystanders and other workers know a forklift is operating in the area?

- What could cause the forklift to roll over?